DTF vs. Screen Printing | Roman Empire Print Shop LLC

Share

When it comes to apparel decoration, screen printing has long been the industry standard. But with the rise of DTF (Direct-to-Film) printing, more businesses, shops, and creators are rethinking how they handle custom prints.

Both methods have their place. Screen printing is trusted for large runs and classic styles, while DTF offers incredible flexibility and speed. Let’s break down the differences, weigh the pros and cons, and see why many are adding DTF to their lineup.

What is Screen Printing?

Screen printing is one of the oldest and most widely used printing methods. It involves pushing ink through a stencil (screen) onto fabric, one color at a time.

Typical Uses:

-

Large quantity orders (50+ shirts)

-

Simple logos and bold spot colors

-

Classic looks for brands, teams, and events

What is DTF Printing?

DTF printing is a newer digital process. Artwork is printed onto a special film, coated with adhesive powder, cured, and then heat-pressed onto the garment.

Typical Uses:

-

Small or large orders

-

Full-color, detailed designs (gradients, photos, shading)

-

Mixed fabric types (cotton, poly, blends, dark or light colors)

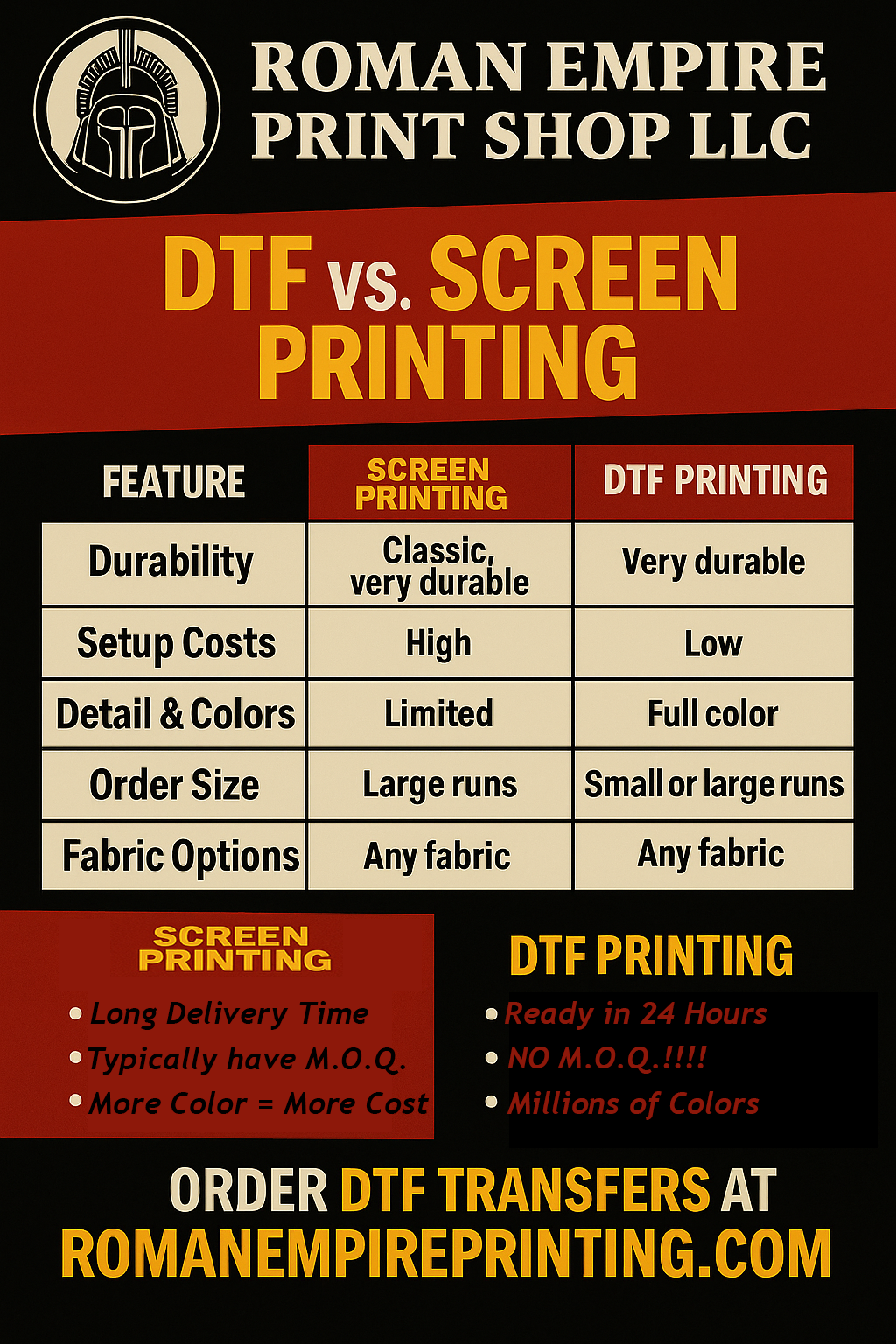

Side-by-Side Comparison

| Feature | Screen Printing | DTF Printing |

|---|---|---|

| Durability | Very durable, especially on cotton | Highly durable, resists cracking/fading |

| Setup Costs | High (screens, films, prep time) | Low (digital process, no setup fees) |

| Detail & Colors | Great for bold designs; limited in gradients | Handles full color, photos, gradients easily |

| Order Size | Best for large runs (50–1000+ items) | Works for 1 item or 1000 — no minimums |

| Speed | Slower upfront (prep), faster on big runs | Fast turnaround (same-day/next-day possible) |

| Fabric Options | Works best on cotton | Works on cotton, polyester, blends, darks, lights |

Pros & Cons of Screen Printing

Pros:

-

Classic look and feel

-

Very durable on cotton

-

Cost-effective for large bulk orders

Cons:

-

Expensive setup (each color needs its own screen)

-

Not cost-effective for small runs

-

Limited detail for photo-like designs

-

Slower turnaround if only a few items are needed

Pros & Cons of DTF Printing

Pros:

-

Works on nearly all fabrics (cotton, poly, blends, darks, lights)

-

Full-color, high-resolution prints

-

No minimums — great for one-offs or small runs

-

Same-day/next-day turnaround possible

-

Cost-effective for shops needing variety

Cons:

-

Slightly different feel (ink sits on top vs. soaked into fabric)

-

Requires heat press equipment to apply

Why More Shops are Adding DTF

Screen printing still has its place — especially for bulk orders of simple designs. But many shops are adding DTF because:

-

They can say yes to smaller orders they’d normally turn away.

-

They can produce full-color artwork without extra setup costs.

-

They can meet fast deadlines without needing to burn screens.

-

It complements screen printing, rather than replacing it.

In other words: screen printing is great for bulk, but DTF lets you take on more customers, more projects, and more profit opportunities.

Conclusion

Both methods have strengths. If you’re ordering thousands of shirts with a simple logo, screen printing may still be the right choice. But if you need fast turnaround, unlimited colors, and no minimums, DTF is the modern solution.

At Roman Empire Print Shop LLC, we specialize in DTF gangsheets and UV DTF decals — ready same-day or next-day for pickup in Montana and Utah.

💥 New customers: Use code REPNOOB for 10% off your first gangsheets order.

👉 Order your DTF transfers today at romanempireprinting.com

Action Plan for You

-

Post this as a blog on your site this week.

-

Add internal links in the article → to your DTF gangsheets product page and UV DTF decals page.

-

Repurpose this content into:

-

A Facebook/Instagram post (with one of the posters we made)

-

A TikTok/Reel voiceover explaining the table in under 30 seconds.

-